|

T: 01268 906591

E:

[email protected]

|

Molybdenum, Tantalum, Tungsten Supplies and Fabrications Ltd |

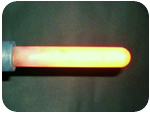

Coated Molybdenum electrode heated at 1000°C

Coated Molybdenum electrode heated at 1000°C

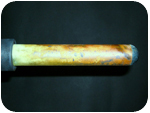

Uncoated Molybdenum electrode heated at 1000°C

Uncoated Molybdenum electrode heated at 1000°C

Coating Furnace

Coating Furnace

Uncoated Tungtsten electrode heated to 1000°C and cooled

Uncoated Tungtsten electrode heated to 1000°C and cooled

New Furnace

New Furnace

Coating Unit

Coating Unit

REFRACTORCOAT

Our unique RefractorCoat process is now located in our dedicated unit at Orwell Court. The coating can be applied to glass melting electrodes, crucibles, furnace fittings, or any Molybdenum or Tungsten part that is heated to a high temperature in atmosphere to give complete anti oxidisation protection.

RefractorCoat will extend glass melting electrode life during start up, up to 500 working hours up to 1750oC. We can offer to free issue coating of your electrodes up to 1200mm in length of any diameter.

RefractorCoat is suitable for all glass types, including quartz, as it contains no Boron and will not gas off or discolour the glass. We have developed the coating to give a diamond like hardness finish that will not crack, peel or flake under any conditions as unlike other sprayed on coatings ours is applied by a high temperature deposition so that it becomes part of piece being coated. The average thickness of coating of any part is between 0.076mm to 0.127mm.

If you have any query or question as to whether our coating will be suitable for your application then please ring/mail Stuart Alexander who can answer all of your doubts as he has over 30 years’ experience in coating parts in a wide range, from furnace parts to Rolls Royce RB211 engine protection shields.

We can also send you F.O.C. a small sample Mo coated rod for you to trial in your furnace.